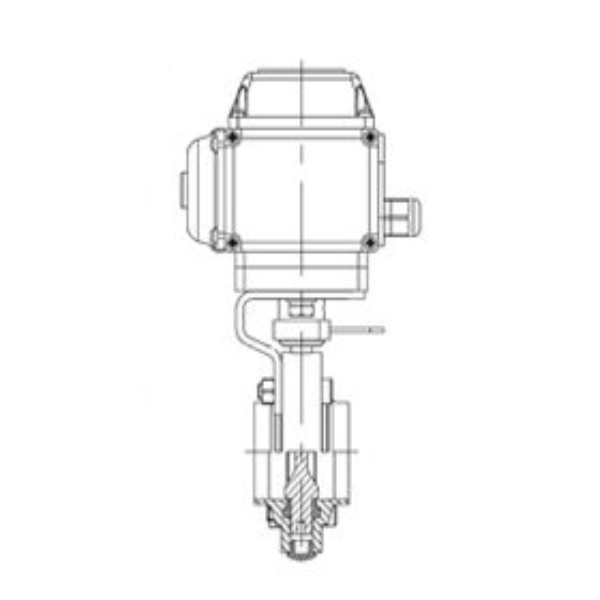

Sanitary Mixproof Valve

Sanitary Mixproof Valve is applied in the industries of dairy, brewery, beverage, chemical, and pharmacy. As a hygienic valve with double sealings, Mixproof Valve is designed to separate two different materials of the piping system to protect the materials from contaminating each other. Compare with single seat valve, mixproof valve save more space to enable the pipeline perform excellently and conveniently.

Design

- Availabe from 1-1/2″ to 4″ (DN40 ~ DN100).

- The body of mixproof valve is with normally closed pneumatic actuator.

- Forged ball type body.

- Compact design.

- Angular orientation 360°.

- Balanced protection design.

- Distinguish whether the gasket is broken or not through observing the leaking tube of the valve bottom

- Easy disassembly.

Material

Stainless Steel 316L or 1.4404 etc.

Strength

- Material of stainless steel 316L and 1.4404 is from reputed mill to guarantee the chemical composition and mechanical propertis. Material certificate will be submitted follow to orders.

- Forged /investment valve body and disc to control the leakage and visual.

- Superior facilities and good experiences for fabrication.

- In ability to improve and develop new design.

- Fast delivery is possible to meet your needs well in time.

- Low cost from bulk production will reduce your budget and improve your business.

- Small quantity available.

Quality & Inspection

- PMI test to verify material grade

- Dimension controlling during fabricating and finished

- Visual and surface 100% examination before shipment

- Packed in carton box firstly, then in wooden case

- Third party inspection available.

Application

Food, Brewery, Beverage, Dairy, Pharmaceutical, Biopharma etc.

Technical Specifications & Options of Sanitary Mixproof Valve

|

General Specifications of Sanitary Mixproof Valve |

||||||

|

Working Pressure |

Max. Working Pressure |

10 bar (4″ is 5 bar only) |

||||

|

Working Temperature |

Continuous Working Temperature |

-10°C ~ +120°C(EPDM) |

||||

|

Surface Finish |

Internal Surface Finish |

R?0.8?m |

||||

|

External Surface Finish |

R?0.4?m |

|||||

|

Connections |

Connection Standards |

DIN, SMS, 3A, RJT |

||||

|

Connection Standards |

Butt Weld, Tri-Clamp, Threaded |

|||||

|

Material |

||||||

|

Metal Material |

Product Wetted |

316L (1.4404) Forged |

||||

|

Other Steel Parts |

304 (1.4301) |

|||||

|

EN 10204 3.1B certificate is available on request. |

||||||

|

Seal Material |

Standard |

EPDM |

||||

|

Options |

FPM(Viton -R), NBR |

|||||

|

All seal materials comply with FDA 177.2600. |

||||||

|

Manual Handles & Pneumatic Actuator |

||||||

|

Pneumatic Actuator |

Standard |

Stainless Steel |

Standard |

Air/Air (A/A) |

||

|

Pneumatic Actuator |

Options |

Normally Closed (NC) |

||||

|

Options |

Plastic Pneumatic Actuator |

Standard |

Air/Air (A/A) |

|||

|

Options |

Normally Closed (NC)/Normally Open (NO) |

|||||

|

Air Supply |

Dry & Filtered Compressed Air |

|||||

*For more information of Santiary Mixproof Valve of Wellgreen, please contact us for details.