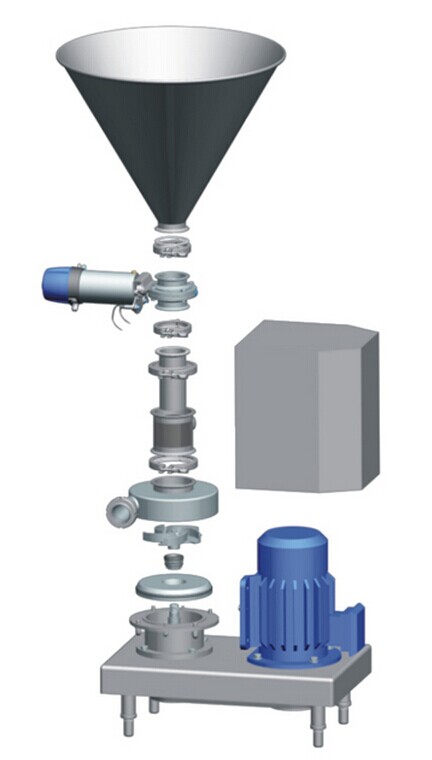

Misturador/Blender sanitário

Misturador sanitário também designado misturador sanitárioA pedido, é fabricado em aço inoxidável 304 ou 316L. Misturador sanitário pode ser preparado para lamas e materiais sólidos, tais como xarope, derivados, leite em pó, cacau, soro de leite, amido, água salgada e outras sobremesas lácteas, também é ideal para a filtragem de vinho, indústria de queijo, pesticidas e fertilizantes. Misturador sanitário pode ser instalado com bomba de lóbulo rotativo sanitária para eliminar bem o material viscoso, também pode ser equipado com um bomba centrífuga sanitária para produzir bem material com elevado teor de sólidos. A Wellgreen fornece vários bombas sanitárias para o seu equipamento de processamento.

Conceção e características

- Design de tipo dividido do misturador e do motor.

- Totalmente em aço inoxidável, boa resistência à corrosão.

- Impulsor de design aberto, baixa resistência

- Ângulo não morto, velocidade de fluxo rápida, mistura eficaz

- Adequado para condições de trabalho alargadas.

- Vários meios, incluindo lama e material sólido.

- Disponível para equipar com outras bombas e válvulas para obter melhores resultados.

- Design higiénico.

Materiais

- Materiais húmidos: AISI 304/316L.

- Outras peças: AISI 304.

- Juntas (standard): EPDM(FDA 177.2600).

- Vedação mecânica (padrão): 304/316L+Graphite/SiC.

- Acabamento da superfície interna: Ra<=0,5?m.

- Acabamento da superfície externa: Ra<=0,8?m.

Princípios de funcionamento

Abrir a entrada de misturador sanitário e fazer líquido na câmara de mistura (cabeça da bomba), o líquido entra na câmara de mistura do impulsor rotativo de alta velocidade, abre a válvula de borboleta controlada da tremonha, bombeando os materiais da tremonha. O material e o líquido serão misturados eficazmente sob a rotação de alta velocidade do impulsor e, em seguida, descarregados. Existe uma válvula de borboleta de ajuste de abertura sob a tremonha para controlar a entrada de material e o fluxo de líquido.

*Nota: A bomba de mistura de material pode ser utilizada como uma bomba de transferência, mas é melhor separá-la se não houver necessidade especial. Quando o bombeamento de material é reduzido ou não pode o material, precisa ser ajustado corretamente e reduzir o volume de fluido da válvula de entrada. Quando a pressão de saída é grande, o volume inalado de material reduzirá muito, se a pressão de descarga ou a resistência for muito grande, uma bomba centrífuga deve ser adicionada na saída do bomba misturadora.

Especificações técnicas

- Fluxo de saída: 10-20T/h

- Pressão de saída: 2,0~3,6bar

- Pressão máxima de entrada: 4bar/58 PSI

- Temperatura máxima de funcionamento: 125°C/257°F

- Potência do motor: 4-7,5kw (motor ABB)

- Frequência do motor: 50Hz/60Hz

- Velocidade máxima de rotação: 2900~3440 rpm

- Tipo de impulsor: impulsor aberto

- Tipo de vedação do veio: tipo de vedação de água, dispositivo de vedação mecânica simples

Opções

- Juntas de vedação: FPM (VitorR) ou PTFE

- Válvulas pneumáticas

- Sensores de nível alto-baixo

- Vibradores pneumáticos ou eléctricos

Ligação

Rosca, Tri-clamp etc.

Quadro elétrico

- Está disponível um quadro elétrico para esta bomba, para proteger o funcionamento do equipamento.

- A função comum de um quadro elétrico normal:

- Ligar/desligar

- Paragem de emergência

- Proteção do motor

Aplicação

Ideal para o processamento em linha de soro de leite, xarope, derivados, leite em pó, cacau, produtos lácteos, filtração de vinho, indústria de fabrico de queijo, pesticidas e fertilizantes, etc.

*Para mais informações sobre bombas misturadoras sanitáriasPor favor contactar-nos.