Rotary Lobe Pumps

Rotary Lobe Pump is a positive displacement designed lobe rotor pump, according to 3A standard with a very strict hygienic requirements to equipment and processes. Rotary lobe pump is ideal for the transferring of viscous materials as well as low-viscous media in the food processing, cosmetics and pharmaceutical industries. Wellgreen provides various sanitary pumps for your processing equipment.

Design and Features

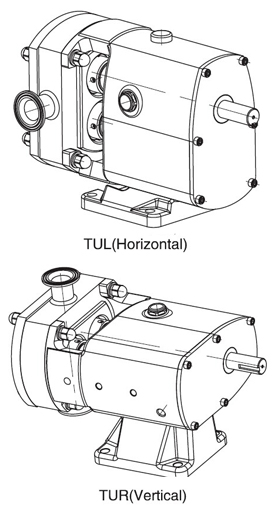

- Horizontal TUL series.

- Vertical TUR series.

- Bare-shaft construction.

- Tri-lobe rotors.

- Hygienic design of the attachment of the rotors.

- Sanitary mechanical sealing, internal assembly.

- Easy cleaning and maintenance.

- Connections: clamp(standard).

- Applied to CIP cleaning and SIP sterilization.

Materials

- Investment casting pump body: AISI 304/316L.

- Cast iron support and gear box: QT450-10.

- Gaskets (standard): EPDM(FDA 177.2600).

- Mechanical sealing(standard): C/SiC/EPDM.

- Internal surface finish: Ra<=0.6?m.

- External surface finish: Mirror polished.

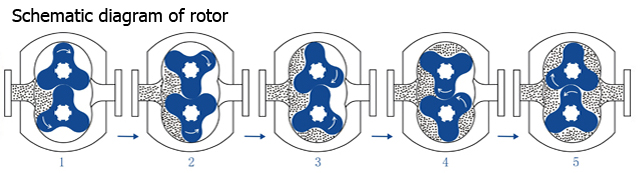

Operating Principles

Rotary lobe pump basically consists of two lobe rotors which rotate inside the casing without touching each other.

As the rotors rotate, the space between the lobes and the casing is successively filled with the product which is driven to the discharge nozzle displacing a fixed amount of product.

The pumped product forms a continous stream due to the adjusted tolerances of the lobes and the pump casing thus ensuring an efficient pumping.

Technical specifications

- Max.flow: 90m3/h/395 GPM

- Max.pressure: 12bar/174 PSI

- Max.working temperature: 150°C/302°F

- Max.rev: 1450 rpm

Options

- Mechanical sealing: SiC/SiC, TgC/ Sic

- Gaskets: FPM (VitorR) or PTFE

- Relief valve at the front cover or external by-pass

- Flushed single or double mechanical seal

- Vertical TUR series or Horizontal TUL series

- Built-in safety valve

- End-face heat jacket

- Complete heat jacket

- Adjustable feet

- Different drives and fixes:

- Manual adjust continuously variable transmission

- Frequency converter adjust motor gear box

- Fixed speed output transmission

- Assembly on a stainless steel baseplate

- Inlet&Outlet Connection: Tri-Clamp, Threaded to DIN, SMS, 3A, RJT, IDF, ISO etc

- Motor type B5, motor frequency 50HZ, 60HZ

- Voltage 220-240, 360-400, 420-460, 630-690 (V)

*For more information about sanitary centrifugal pumps, please contact us.