Sanitary Diaphragm Valve

Sanitary Diaphragm Valve is specially designed for  sanitary and aseptic pipeline due to its double sealing system both of valve’s body and seat. Manual or automatical operated and welded or clamp end, direct or three ways, diaphragm valve provides convenience and asepsis to control the flow. Wellgreen offers various types stainless steeel sanitary valve to meet variety needs of hygienic industries of Food, Brewery, Beverage, Dairy, Pharmaceutical etc.

sanitary and aseptic pipeline due to its double sealing system both of valve’s body and seat. Manual or automatical operated and welded or clamp end, direct or three ways, diaphragm valve provides convenience and asepsis to control the flow. Wellgreen offers various types stainless steeel sanitary valve to meet variety needs of hygienic industries of Food, Brewery, Beverage, Dairy, Pharmaceutical etc.

Products

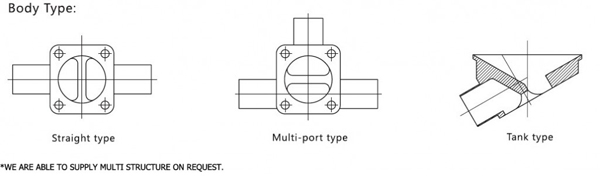

- Sanitary 3 Way Diaphragm Valve

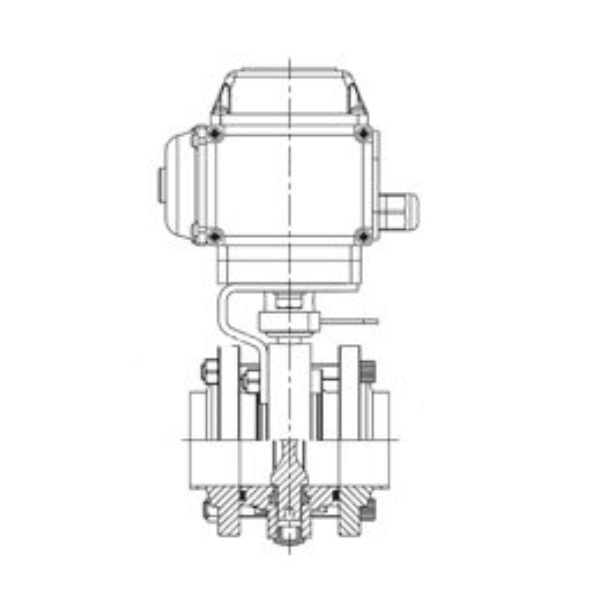

- Sanitary Welded Diaphragm Valve

- Sanitary Tri-Clamp Diaphragm Valves

- Sanitary Threaded Diaphragm Valves

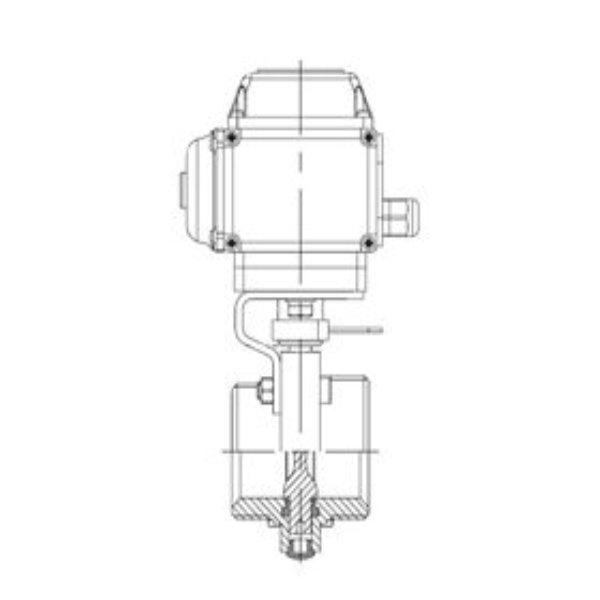

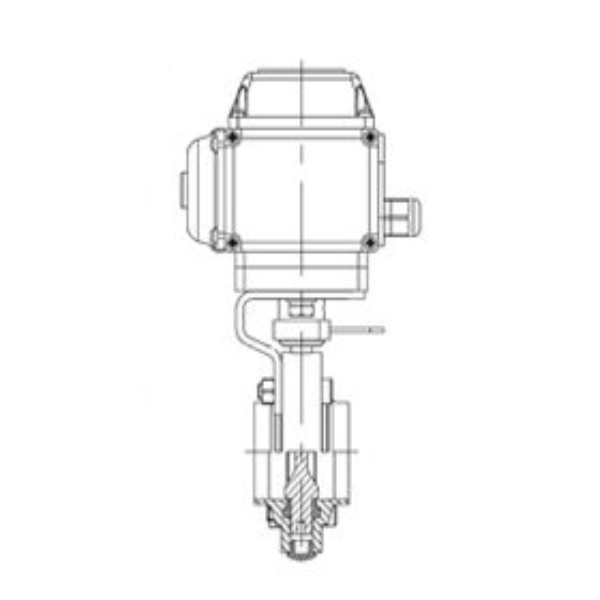

- Pneumatic Actuated Diaphragm Valves

Material

Stainless Steel F316L, F304 forged etc.

Diaphragms

The diaphragm made with Softness and elastic material is not sensitive for the working medium which polluted by fabric, solid grain, catalyze object, etc. In general, it also will not affect the valve working and sealing condition. We select the right diaphragm material such EPDM, Code, 1/3A, 16/6A, or FPM/Viton, Code 4 and 4A etc. according to the working/sterilizing temperature, and the chemical identity of working medium.

Design

-

Superior hygienic design — The opening or closing of diaphragm valve is controlled by a diaphragm which ensures absolute isolation of internal pipeline and external environment. The valve is applicable to the aseptic process.

- Simple structure, easy cleaning and maintenance — our food grade diaphragm valve is composed of a few removable parts (a valve body, a diaphragm, a handle or actuator), no special tools are required.

- Unique Diaphragm Design–The diaphragms are available in soft elastomers (EPDM/FPM/Q) as well as hard elastomers (PTFE).

- Sanitary diaphragm valve is excellent for flow control as well as for open/close duties.

Strength:

- Forged stainless steel F316L, F304.

- All diaphragm seal consistency with FDA certificate.

- Both manual and automatical operated and multi-connection for every needs.

- The design of diaphragm valves are better in feature of flow in comparison with other valves.

- The diaphragm valve is excellent for flow control as well as for open/ close duties.

- Easy to clean up and better to process the substance with particles.

- All synthetic resin and additive are comply with FDA certification.

- The valve is excellent for flow control as well as for open/ close duties.

- Multi-design on specialised request.

Quality & Inspection

- PMI test to verify material grade

- Dimension controlling during fabricating and finished

- Visual and surface 100% examination before shipment

- Packed in carton box firstly, then in wooden case

- Third party inspection available.

Application

Food, Brewery, Beverage, Dairy, Pharmaceutical, Biopharm etc.

Technical Specifications of Sanitary Diaphragm Valve

| Valve Material | Contact product parts | 316L(1.4404)Forged |

| Non-contact product parts | 304(1.4301) | |

| Sealing Material | Standard | PTFE/EPDM Composite diaphragm |

| Option | EPDM, Silicone, FPM

comply with FDA 177.2600 |

|

| Temperature | Running working temperature | -20 ~ +135°C(PTFE/EPDM) |

| Sterilization temperature | 150°C (Max20min) | |

| Pressure | Working pressure | 0-10bar |

| Control air pressure | 5-8bar | |

| Finish Condition | Internal surface | Ra?0.4um (mirror polish or electronic polish) |

| External surface | Shot-blasting | |

| Connection | Connection standard | Welding end: DIN 11866 series 3 and series 1 |

| Connection method: welding, thread, tri-clamp, flange | ||

| Option | Intelligent controller | 24V DC

1 electromagnetism valve |

| Position sensor | 2 NPN/PNP position sensor | |

*For more information of sanitary diaphragm valves, please contact us for free.